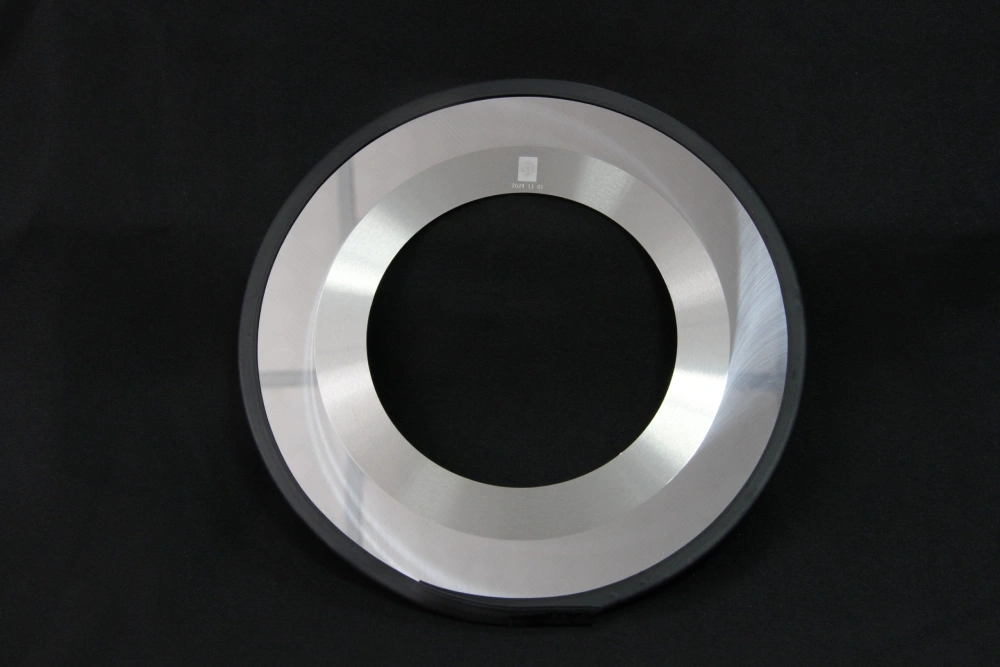

Tungsten steel knife series

Description

Typical size

Common problems in the use of corrugated paper vertical cutting knife

Problem 1: The short lifespan of corrugated board blades.

A. Is the grain size of the grinding wheel adequate? Too coarse a grain size of grinding wheel shortens the lifespan/performance time of blades.

B. Excessive grinding: the grinding interval is too short or the grinding pressure is too high.

Problem 2: The edges of corrugated boards cut by blades show burrs and dents.

A. Please check the cutting edge of your blade. Is the cutting-edge sharp enough?

B. The corrugated board is too wet.

Problem 3: Breakage of blades.

A. Incorrect assembly e.g., deformed flange plate, wrong screwing will cause the breakage of blades.

B. Unstable swing grinding wheels break the blades; please check the bearing of the grinding wheels.

C. The problem may be caused by collision with other hard objects.

Problem 4: Chips on the cutting edge after the grinding.

A. Unstable swing grinding wheels may cause this problem, even break the blades.

B. A collision with hard objects may cause the chips on the cutting edge.

Problem 5: The edge of corrugated board is not straight.

A. The hardness of the blade and corrugated board might not match.