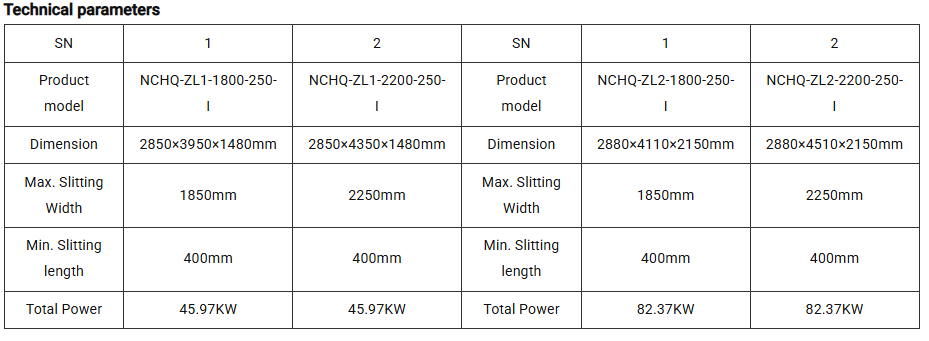

CORRUGATED BOARD PRODUCTION LINE DRY END SERIES High Speed Spiral Blade Cutoff Machine (Single Layer, Double Layers)

Improved CodeI, generation I; Ⅱ, generation II etc.

Line Speed: 300m/min

Working Width: 1800, 2200,2500,2800

ZL1: single layer direct connection; ZL2: double layer direct connection

NC Cutoff Machine

Electric & Pneumatic part

PHASE driving Servo Motor

Shandong Li Jiu VF Motor

Pneumatic components from SMC, Air Tac

Corrugated board cutoff machine

Actuation Part

Gearboxes are made of HT300 high-quality gray cast iron, and characterized by aging treatment and precise processing.

Blade rollers are precisely machined and characterized by dynamic balance correction, high rigidity and small inertia.

High-speed tool steel cutter

Transmission Part

Due to imported elastic coupling, the equipment can efficiently work at high speed for a longer service life.

Gears are made with top alloy structural steel (20CrMnTi) which is carburized and quenched so that the operation stabilization of equipment is improved.

The exiting and feeding boards are stably conveyed by a synchronous belt, reducing noise and ensuring board-exiting and feeding structures run synchronously.

NSK, IKO, HRB precision bearings

Control Part

Cutoff Control: Emerson AC servo controller, Lenze AC servo controller

Energy Storing Device: 30% of energy can be saved through the high-efficiency energy-saving module

Monitoring Control: Schneider or Siemens PLC, Sick series sensor

Low-voltage Apparatus: Schneider

General Introduction to Equipment

With high or mid-speed corrugated board production line, it could realize full computer control, auto order changing, and high speed slitting of different lengths of boards. By combining with advanced control mode and high quality machine designing, the needs of customers are fully met and the JUSTU innovation is fully embodied.

Functional Feature

Use high quality industrial computer or human-computer interface to form master computer control system;

The equipment is driven by AC servo motor, and the driver is controlled by the imported servo drive controller;

The equipment can be connected with production management system to realize non-stop order changing or manual order changing;

The blade rollers are of double spiral structures, so that the slitting force is small, efficiency is high and transmission is stable;

The spiral blade is made of special material, and blade roller is reasonably structured and could serve long service life.

Mechanical structure is rationally designed, and the board feeding part is connected with the master machine through the guide rails, so that blades are easy to adjust;

Use precision gear transmission where the gears are made by forging, fine processing and hot treatment etc.

The gears feature small side clearance, low noise and stable transmission.

High slitting precision: ≤ ±1mm at constant speed, ≤ ±1.5mm while accelerating and decelerating;

Line speed is no more than 250m/min